Our Technical Director

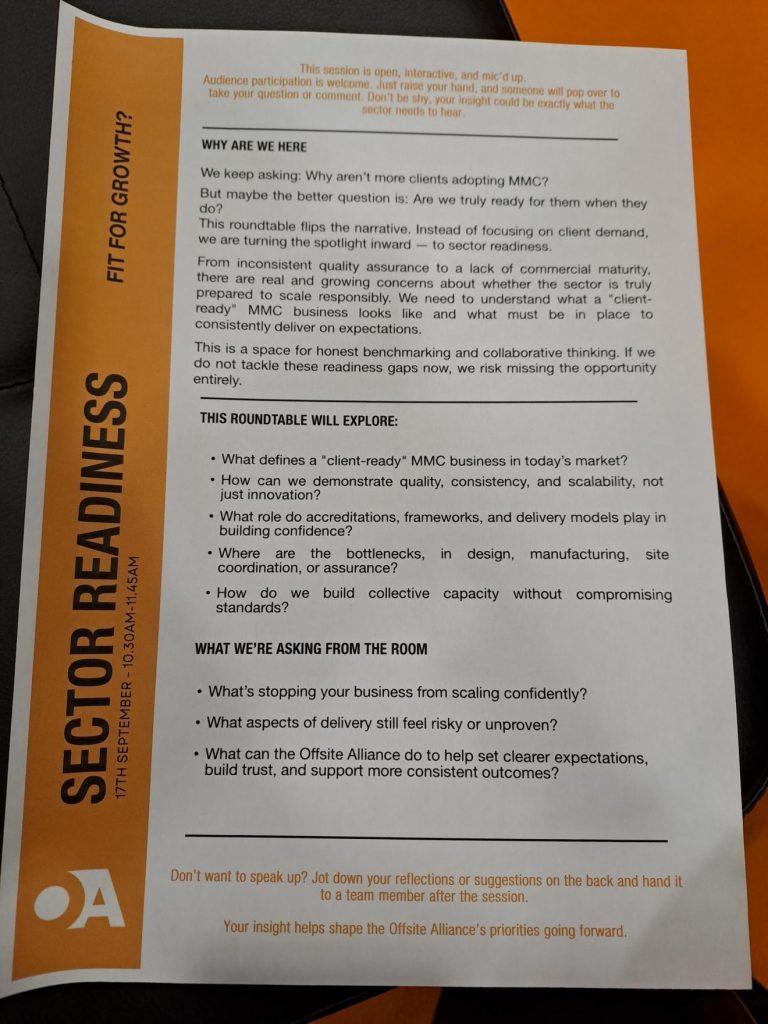

Steven Marshall attended an industry roundtable at

The Offsite Expo, and was asked a deceptively simple but critical question:

“Instead of asking why more clients aren’t adopting Modern Methods of Construction (MMC), should we be asking whether the sector is truly ready for them when they do?”

The discussion was candid, energising, and refreshingly practical. Fellow panellists shared powerful insights, and the high level of audience participation underlined a shared appetite for honest dialogue about where we are and where we need to go.

In many conversations about MMC, the focus drifts quickly to capacity: How many homes can we produce? How fast can factories scale up? How much pipeline can we deliver?

But true readiness isn’t measured in capacity alone. It’s measured in predictability and trust.

For clients, building control officers, and warranty providers, MMC must be something they see as:

-

Reliable — consistent outcomes, not one-off pilots.

-

Risk-free — backed by transparent assurance and proven quality.

-

Regulation-exceeding — not just meeting the minimum, but setting the benchmark.

Until MMC is seen in this light, its adoption will remain limited in the housing sector.

One theme I emphasised was the importance of standards in shifting MMC from the “new and innovative” box into the “trusted and proven” category.

The work being done through the

British Standards Institution (BSI) including the recently published

PAS 8700:2025 and the work Steve is doing at BSI on

CB/301 is a pivotal step forward. Clear, consistent frameworks will help unlock barriers to entry and give every stakeholder across the value chain the assurance they need.

Standards don’t stifle innovation. They enable scale. They allow clients, regulators, and insurers to engage with MMC with confidence, knowing they are investing in something robust, not experimental.

Perhaps most overlooked in the MMC conversation is the role of the supply chain and the distributor.

In traditional construction, supply chains are often treated as transactional. In MMC, they are strategic. Distributors are:

-

Integrators — connecting manufacturers, contractors, and sites.

-

Gatekeepers — ensuring consistent quality, sequencing, and compliance.

-

Scalers — aggregating demand and capacity to enable growth.

At

Galaxy Technical Services, we have focused on delivering bespoke technical services into MMC offering true value into the supply chain. By taking a proactive role in logistics, assurance, and delivery, we’ve seen how distributors can add tangible value to the ecosystem — helping MMC to deliver at pace, at scale, and with confidence.

The MMC sector has a generational opportunity. But that opportunity will only be realised if we can collectively move MMC out of the realm of novelty and into the category of reliability.

That means:

-

Focusing less on raw capacity and more on predictable outcomes.

-

Building standards that unlock trust across the ecosystem.

-

Elevating distributors and supply chains from afterthoughts to central enablers.

The roundtable left Steve encouraged. The insights from peers, and the level of debate in the room, showed a sector ready to be self-critical and collaborative. If we continue in that spirit, MMC can move from being “innovative” to being a trusted solution to the UK housing shortage.